What Chemicals Are Used in Bathtub Refinishing?

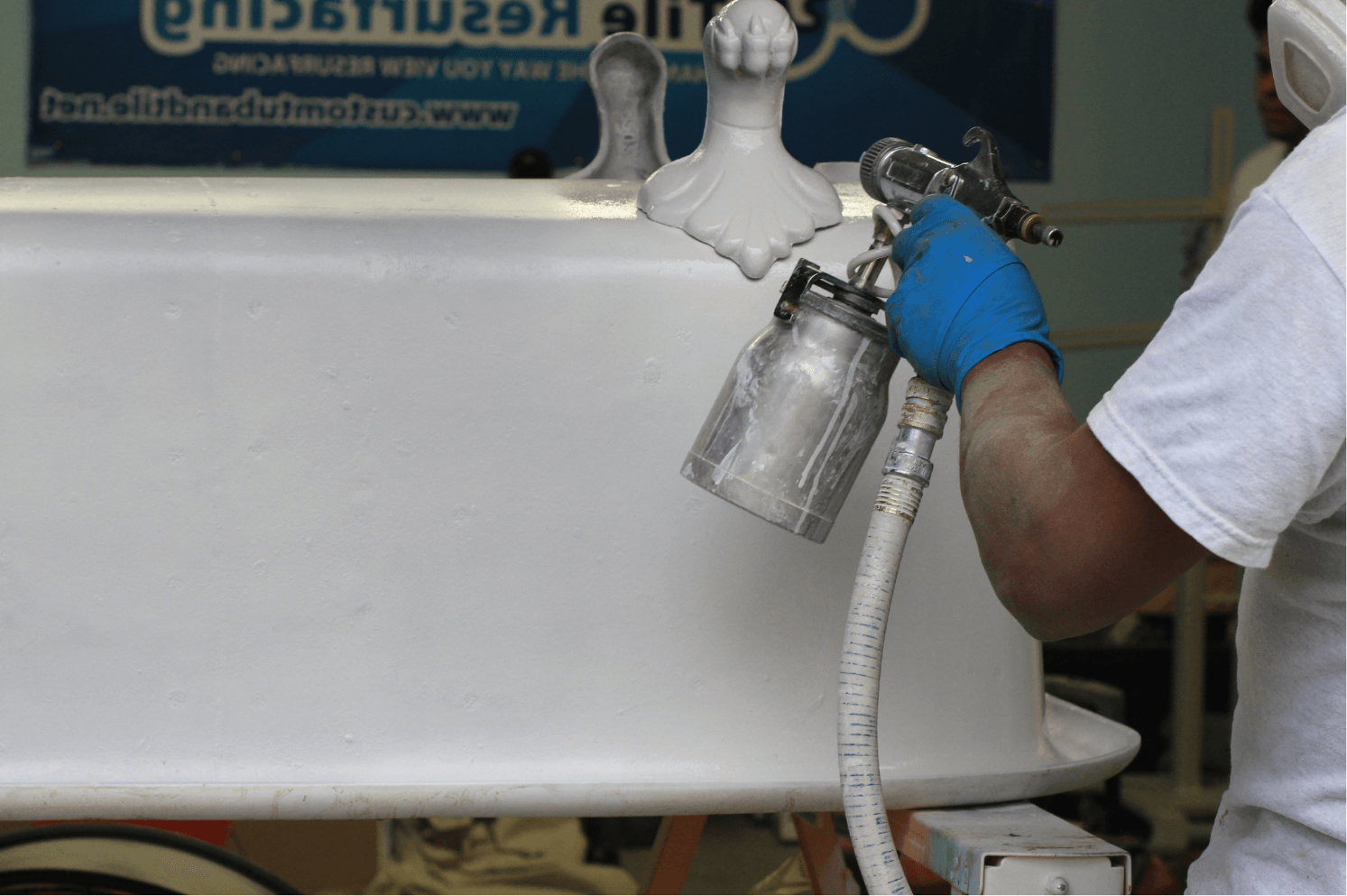

By now, many people know that refinishing a bathtub beats replacement. For those of you who are intrigued by refinishing, we understand your interest. Refinishing offers a cost-effective and hassle-free alternative to ripping out your old tub. It’s easy to picture the devastation inflicted on your poor bathroom: gutted edges, stains, sliced-up floors and walls, not to mention the inconvenience of finding another place to — well, you know.

If you’re wondering how refinishing actually works and, specifically, what chemicals are used in bathtub refinishing, then you’re reading the right guide.

In this outline of the refinishing process, we’ll give particular focus to what chemicals are used to resurface a bathtub. After all, the chemicals and paints perform the main roles in the refinishing operation. Knowing which chemicals commonly get used will help dispel the mystery of this amazing process.

Some people hear the names of these chemicals and don’t know what to think. What purpose do these chemicals fulfill? What options exist for choosing one chemical technique over another? What are the pros and cons of each chemical? If you find yourself asking any of these excellent questions, there’s good news — we’ve got the answers!

Knowledge and Safety

It pays to know what chemicals are used in bathtub refinishing for a number of reasons. First, it demystifies the process. As a consumer, it’s always better to educate yourself before making a decision. You’ll feel more informed and relaxed when the technician comes and starts spraying chemicals.

Which brings us to the second point: it’s wise to know the nature of the chemicals you let into your home.

Some of the chemicals used in bathtub refinishing pack a punch. We’ll go into the jobs each one performs later. For now, it’s good to know that only a trained professional should ever attempt the task of bathtub refinishing. An experienced technician knows the right precautions to take when dealing with these chemicals.

The chemicals and paints used often emit powerful smells. These hefty odors can cause irritation if inhaled. When professional refinishers come to your home, you’ll notice them wearing proper breathing masks. Ventilation tubes also ensure the chemical fumes safely exit your home. With proper precautions, these chemicals are perfectly safe. Unfortunately for those DIY aficionados out there, we don’t recommend you even think about attempting a bathtub refinishing project alone. The project simply requires too much specialized knowledge and safety considerations.

However, you don’t need a HazMat suit for the chemicals we’ll discuss. In fact, for smaller and tamer home projects, feel free to explore using some of the paints. Many of the paints used in bathtub refinishing appear in a number of everyday home repairs. These paints require proper care and caution, but if you wear a good-quality paint mask and properly ventilate your work area, your project should meet standard safety levels.

As with any project, before you begin, educate yourself on the nature of the products you plan to use. This guide will certainly help you learn which chemicals and paints are present in bathtub refinishing, but knowledge doesn’t confine itself to one arena. Ask questions and learn more about which chemicals do what, and what their composition entails.

The Chemicals Themselves

Okay, enough preamble — let’s learn about what chemicals are used in bathtub refinishing. We’ll focus specifically on three chemical paints:

- Polyurethane

- Epoxy

- Acrylic polymers

We’ll give an overview of these chemicals and how they apply to bathtub refinishing. By comparing and contrasting them, you’ll gain a greater knowledge of which type of chemical paint best fits your needs. We’ll also discuss the features of acid etching, which more highly damaged bathtubs may require before undergoing the standard refinishing process.

Polyurethane

Polyurethane retains a reputation as a common type of paint for many household tasks. Polyurethane often gets used to refinish wooden furniture, walls or even antique cars. For our purposes, we’ll discuss how it works for bathtub and countertop refinishing, but this paint boasts a long list of possible uses.

So what is polyurethane? Essentially, this product comprises a combination of plastic paint resins. In addition to its plastic ingredients, polyurethane frequently contains vegetable oil acids, nitrogen-derived parts, mineral spirits and isocyanates. You might not know these last two components, so we’ll quickly tell you what they mean:

- Mineral spirits refer to a petroleum-derived product used to perform the task of paint thinner. However, mineral spirits outperform traditional paint thinners in a number of ways. Paint thinner doesn’t boast the refinement of mineral spirits. Therefore, it often emits a more potent smell. It also contains a higher volatility than mineral spirits, which makes it a poor choice for combination.

- Isocyanates come from organic compound ingredients and react with other elements in the polyurethane to produce the trademark ability of polyurethane to not melt when heated and to form a long-lasting coat.

Specifically, these isocyanates react with the polyol alcohols in the polyurethane mix. The bond of these two chemicals produce the complex molecular structure known as polymer. In short, polyurethane is a polymer. Chemistry aside, polyurethane does an excellent job.

To recap how the ingredients react: Isocyanates increase the strength and heat resistance, and mineral spirits reduce the volatility and aid in the amalgamated product’s stability. The nitrogen elements protect the painted surface from becoming brittle.

You might miss the final ingredient in the polyurethane combo, but it’s right under your nose. In fact, it’s all around you. Yes, oxygen plays a vital role in the chemical process, which produces the ideal polyurethane painted surface.

Water-Based Polyurethane

Water-based polyurethane offers a less smelly alternative to traditional polyurethane. Although not every water-based polyurethane product works well with bathtub refinishing, it’s helpful to know it’s available for other home projects.

Bathtub refinishing requires a fairly heavy-duty polyurethane product to properly seal in the freshly varnished surface. Unfortunately, the water-based polyurethane products just don’t stand up to the task. They occasionally chip and don’t maintain the same longevity as oil-based polyurethanes.

However, water-based polyurethane does maintain some advantages over its oily relative. For one, it dries much faster than oil-based polyurethane and smells less, too. Of course, you’ll still need to properly ventilate any area in which you use water-based polyurethane. But at least you can use it yourself for small projects or retouches.

Traditional polymer polyurethane remains the champion, compared to its watery competitors, for the challenge of bathtub refinishing.

Tips for Home Use

If you’re considering using polyurethanes at home for small projects, it’s wise to consider some common tips to achieve the best results.

For instance, never shake a can of polyurethane. Doing so creates bubbles, which remain in the paint mixture and create an unsmooth final finish. Instead, use a wooden mixing stick to slowly stir the paint. When applying the paint, use a high-quality brush and paint along the natural grain of the wood in smooth, even strokes. Afterwards, use a high-grain sandpaper to gently eliminate any undesired unevenness of the coat, such as streak lines.

Finally, add another coat, let dry and finish with an even higher-grade sandpaper. This achieves the perfect final effect: a beautiful, smooth, glossy finish.

Epoxy

Epoxy refers to an adhesive paint derived from polymers. We already mentioned polymers as complex organic and synthetic molecular structures. So how do epoxies relate to polymers? Epoxies, also known as epoxy resins or polyepoxides, differ in the cured nature of their final state. This curing, or hardening, gives epoxies their trademark fast-drying ability and strength.

Epoxies achieve this super chemical bonding through their ingredients. Two main techniques exist for epoxy resins in utilizing their components: cross-linking or co-reaction. Although you’re likely unfamiliar with these chemistry terms, we’ll simplify the process.

Cross-linked epoxies link one polymer chain to a different one. Keep in mind that polymer chains comprise numerous strings of molecules in themselves. This combination determines the epoxy’s final properties. Cross-linking polymers includes any variety of synthetic or organic linking.

To give you an idea, organic polymer molecules often include proteins or vegetable oils, while synthetic relates to plastics. It’s a wild west for epoxy combos — anything that cross-links and provides a stable bond will likely do the job. The technical term for this polymer-to-polymer amalgamation is “catalytic homopolymerization.” “Catalytic” refers to a chemical catalyst at the moment of successful bonding and “homopolymerization” just means it’s a polymer-to-polymer reaction.

The other type of major epoxy creation technique, called co-reaction, involves putting a polymer together with a non-polymer. The most common types of non-polymers selected for epoxy formation include alcohols, acids and phenols. Phenols, also called carbolic acid, bond easily to hydrocarbons such as plastics or petroleum derivates.

But before we fall down the rabbit-hole of co-reactant chemical compounds, let’s get back to epoxy and our other two superstar chemical paint champs.

Acrylic Polymers

This type of paint firmly belongs in the polymer (plastics) camp. Their natural composition makes them a highly valued option for many industrial demands.

Acrylic polymers represent perhaps the most versatile of the types of paints we’ve reviewed so far. They come out on top in virtually every category. Acrylic polymers boast a reputation for their transparency, natural luster, elasticity and durability.

These factors combine to make acrylic polymers an ideal candidate for bathtub refinishing. The quick dry-time of acrylic polymers also contributes to their incredible usefulness in the application process. Acrylic also offers perhaps the least expensive option. Its ubiquity contributes to this commonly lower price. Acrylic polymers are in everything, from nail polish to fine art painting.

Most importantly, acrylic polymers stand as the safest option for bathtub refinishing. To highlight this aspect, let’s investigate some unhealthy shortcomings of one of our other former contenders: polyurethane.

Polyurethanes contain the harmful isocyantate chemical which can induce asthma over periods of prolonged exposure. Meanwhile, acrylic polymers possess the same compositional features that normally make polyurethanes a desirable choice. Specifically, acrylic polymers boast the same gloss retention, durability and hardness as polyurethane — except they don’t have isocyanates. Nothing is worth risking yourself or your loved ones to this harmful chemical. Stick with acrylic polymers and kick polyurethanes to the curb.

Additionally, unlike epoxy, acrylic polymers don’t yellow over time. Epoxies also get dull and brittle as time goes on, whereas acrylic polymers retain their luster.

These reasons give acrylic polymers a substantial advantage over other options. It’s difficult to find any significant drawback regarding their role in bathtub refinishing.

Before we conclude our investigation into the world of bathtub refinishing paints, it’s helpful to touch on one final aspect of the refinishing process: acid etching.

Acid Etching

Some porcelain or enamel tubs undergo severe chipping, scratching and divots over the course of their lifetimes. Even tile walls see their share of abuse. But unlike acrylic fiberglass baths, these tubs and tiles maintain a much stronger surface. As a result, simple sanding methods don’t always work on these porcelain or enamel surfaces. In such cases, something a little stronger gets called in to do the heavy lifting.

Hydrofluoric (HF) acid has become the most common material used for acid etching. Essentially, HF acid corrodes the surface of the bathtub. This controlled process creates a rough pattern on the surface of the tub. This microscopic texture permits the paint to adhere. This technique, known as mechanical adhesion, applies to many fields of industrial repair.

Most bathtubs and tile walls require only a slight amount of diluted HF acid to accomplish the job. The adjacent drains, siding areas, and floors get securely covered to prevent exposure. After the acid etching completes its job, the technician simply neutralizes the acid and safely washes the solution down the tub drain or safely disposes of the mixtures that is wiped onto the tile walls.

This process may sound simple, but never attempt to perform an acid etching job yourself. Unless a trained technician performs the etching, significant damage, danger and negative environmental effects could occur. Leave this one to the pros.

Enhancing Your Chemical Education

Now that you know your chemical basics, hopefully the process of bathtub refinishing seems less alien. You know the basic chemical compositions of not only epoxy, acrylic polymers and polyurethane, but also the different types of polyurethanes and how they react and bind — and why acrylic polymers are the hands-down winner.

You learned about how acid etching uses HF acid to corrode a bathtub into the perfect receptacle for the paint. You also learned about the hazards inherent with improper handling of these acids, chemicals and paints.

As you continue your exploration into the world of bathtub refinishing chemicals, remember to ask questions. We at Custom Tub & Tile Resurfacing respect inquisitive minds. Our goal centers on providing customers with the best information possible. We love to educate our clientele on the chemicals we use when refinishing bathtubs, countertops or other projects.

A well-informed customer ensures comfort, trust and relaxation. We strive to back up our quality service with the desire to answer any questions you have regarding the amazing and transformative process of bathtub refinishing. Feel free to contact us for more information about which chemicals we use and the processes in which we use them.