Standard Tub Resurfacing

What’s involved with the standard bathtub resurfacing process?

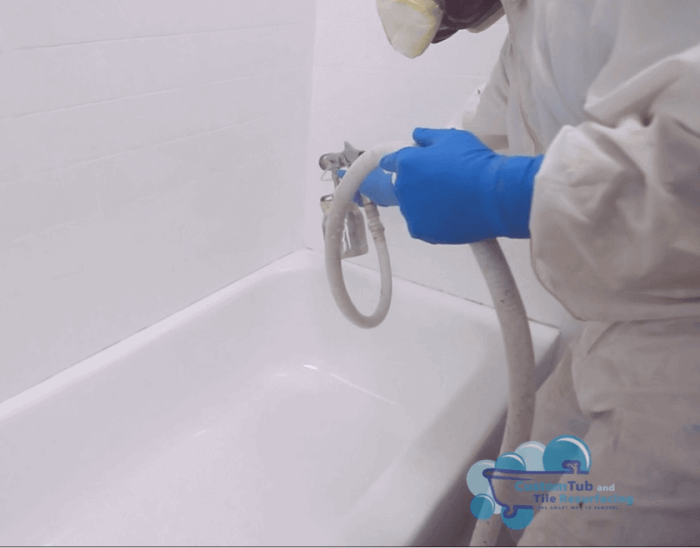

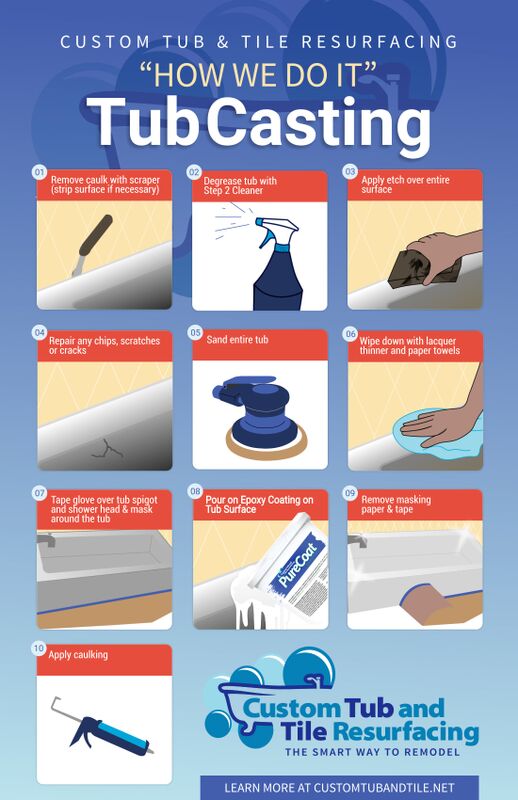

To start, we apply a chemical etching substance that removes the gloss from the tub and makes the surface more porous. Then we coat the unfinished surface with a high-gloss, polymer topcoat that returns your old tub’s gleam and luster. But before we start resurfacing your standard size bathtub, we will protect your bathroom floor and other components by laying a plastic tarp on the floor and over surrounding walls. We take extra care to protect everything not being resurfaced from the etching solution.

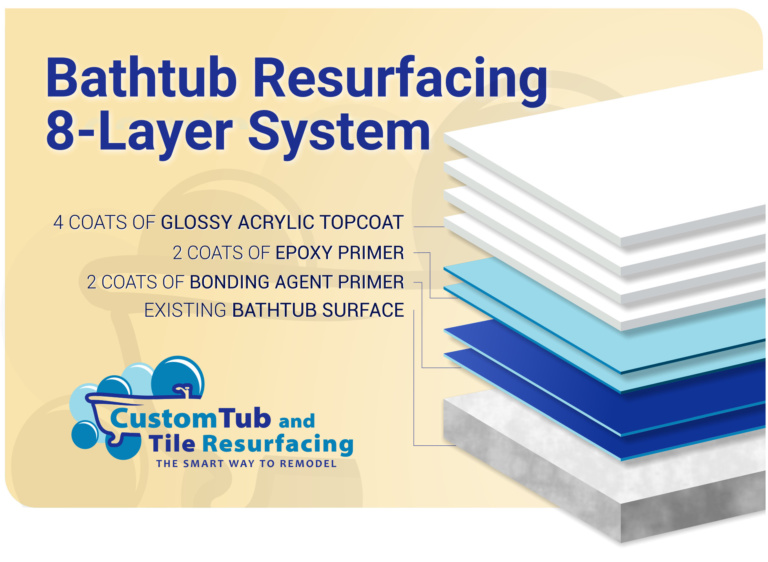

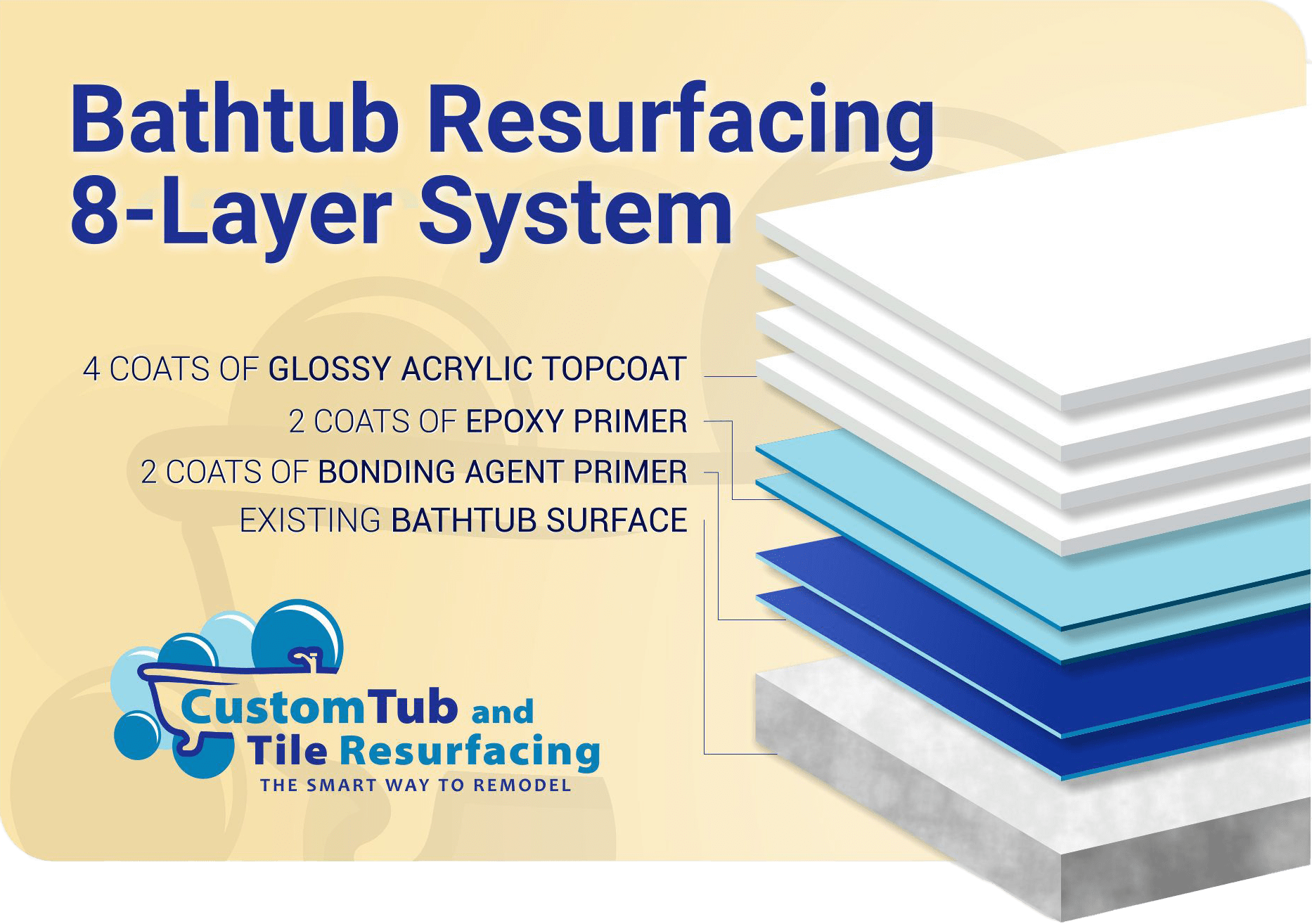

The resurfacing process involves primer and paint materials that are applied using an industry-specific sprayer. In order to achieve a professional appearance, the primer and paint must be sprayed as evenly as possible over the entire surface of your standard size bathtub. It is important to keep the spraying in motion continuously while making sure the right amount of paint is placed on your bathtub. We do not recommend that you try to resurface your family’s bathtub using over-the-counter products and instructions from amateur websites.

What does standard size mean?

What does standard size mean?

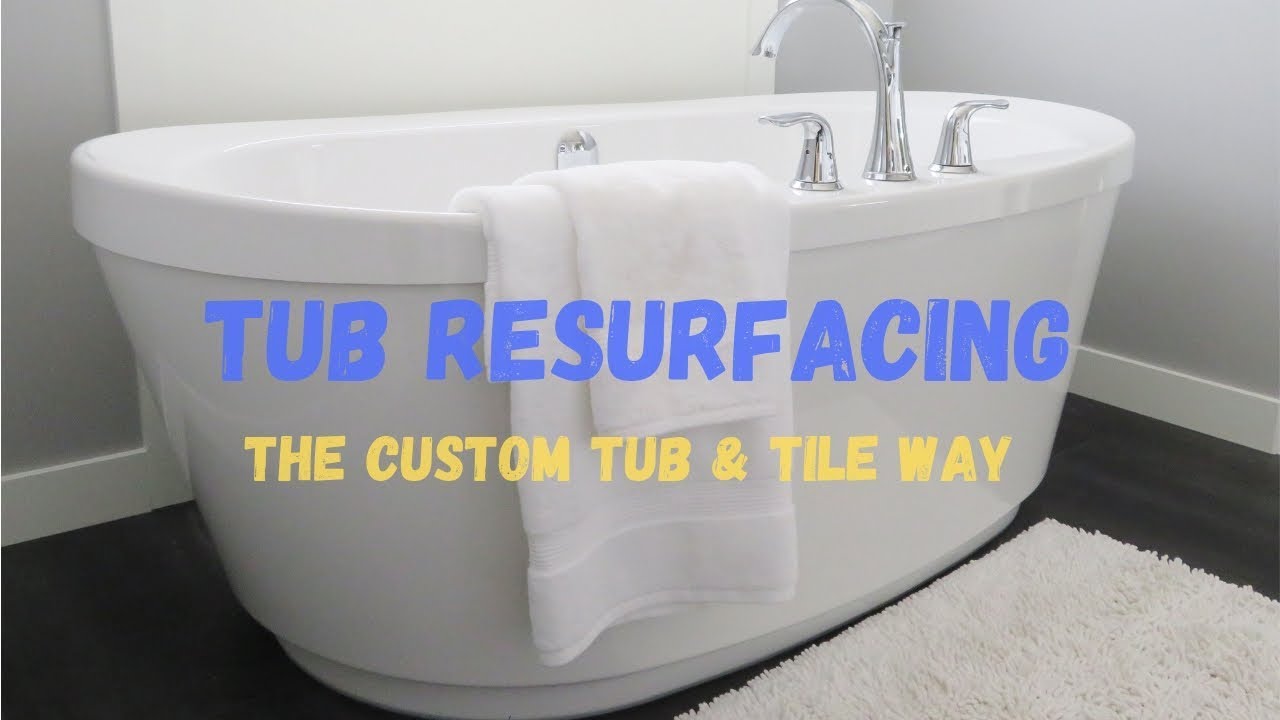

Typically constructed of cast-iron or fiberglass, standard sized bathtubs are a staple in almost every home. Older cast-iron tubs were lined with porcelain, and still exist today due to their durability. More modern and lightweight fiberglass tubs became more popular due to their affordable price and strength that simulates real cast iron.

Standard size tubs are typically surrounded by three walls of tile that go three quarters of the way up the wall. And the tub is built into the wall and not free standing like an antique clawfoot tub. Sliding glass shower doors were once a popular fixture on standard size bathtubs but trends have shifted with shower curtains becoming more favorable.

With standard size tubs being one of the most consistently used part of any bathroom, most standard size bathtubs experience their fair share of abuse throughout their life. Restoring a standard size tub to its original, pristine condition doesn’t mean slapping a coat of paint on it and expecting the paint to remain. Let our refinishing specialists reglaze your family’s standard size tub with the appropriate materials so that it looks like you just moved in.

If You Like Standard Bathtub Resurfacing Then You’ll Love PureCoat Tub Casting!

If You Like Standard Bathtub Resurfacing Then You’ll Love PureCoat Tub Casting!

While we know you will be very happy with the new look of your tub and you can expect it to last a long time, our resurfacing treatment will not keep your tub looking like new forever. The same elements that caused it to crack, chip, stain or generally look worn-down the first time will probably do so again, although you can delay the inevitable with good tub care.

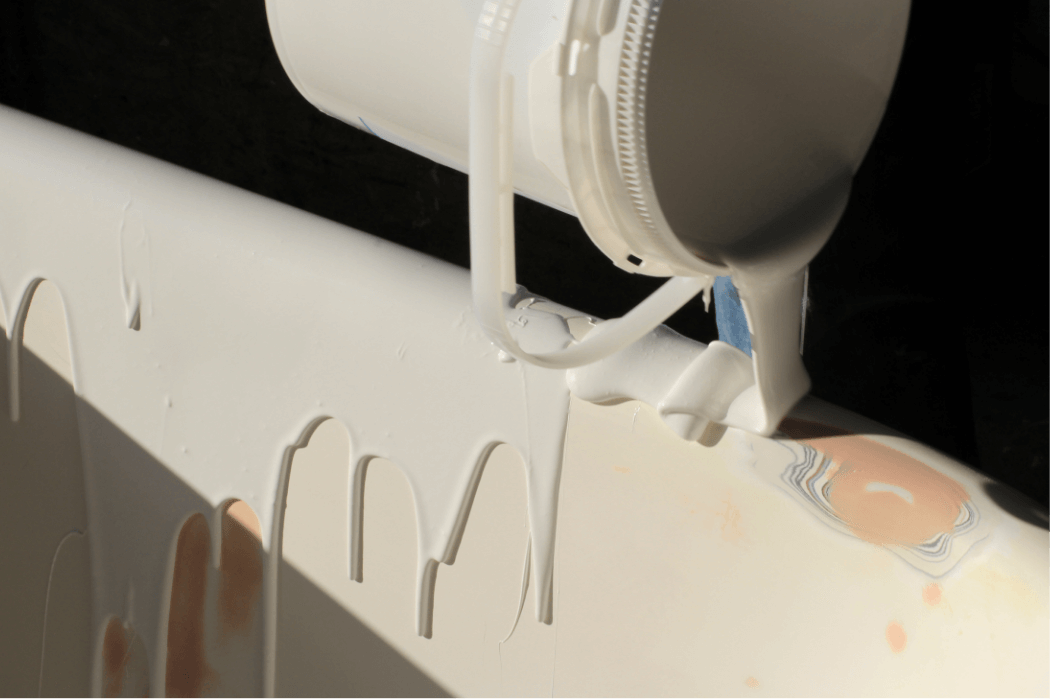

However, we now have a more permanent solution. If you’re interested in a refinishing treatment that can last over 10 years, ask us about our bathtub casting service. Our exclusive bathtub casting treatment uses a special PureCoat mixture that is five times thicker than the standard mixture and creates a layer of protection over your tub that resists suction cup marks, bleach and other hazards that typically ruin the surface of your tub.

Give us the day for the refinishing procedure and 24 hours for the coating to set, and you’ll have a finish for your tub that you will not have to redo anytime soon. This procedure could protect your tub and keep it looking great for many years to come.

When Bathtub Casting is set against the costs of repeatedly resurfacing or replacing your tub, the value is clear — especially when you take the 5-year warranty into account. Our odorless, environmentally friendly casting process is proving extremely popular and we would love to share it with you.

To learn more or for an estimate on bathtub casting for your tub, call us at 240-668-4208 today.

Can My Tub be Repaired?

Chances are, yes! Rust mostly occurs around the drain and overflow plate which can be repaired. While we cannot fully inhibit the rust from forming once it has started our process can slow it down. Our trained technicians use a combination of acid etch and elbow grease to remove the affected metal. The acid etch eats away at the rust which leaves the bare metal exposed and ready for the new surface, and the technician sands away and rust that was not eliminated by the acid etch. Oxidation can severely damage your tub but as long as the structural integrity of the tub is not compromised it can usually be repaired during the tub resurface.

What Can’t be Repaired?

It is important to keep in mind that resurfacing is a cosmetic fix, meaning that some tubs just cannot be repaired. In most cases these are fiberglass tubs or shower pans. Overtime that fiberglass becomes more brittle and flexes and eventually cracks due to pressure from use, structural, or otherwise. If the cracks leak then the tub or shower pan will most likely need replacing. While resurfacing can mask the appearance of the cracks it cannot prevent their eventual return.

Learn More About What Can’t be Repaired by Checking Out Our Blog Post:

What will your own resurfacing success story look like?

We’re Ready When You Are

We invite you to look around our site and learn more about our services, pricing and options. If you want to talk to any of us about the work we do, we’d be more than happy to hear from you, so give us a call at 240-668-4208 anytime!