What is bathtub casting?

Bathtub casting is the latest and greatest development in bathtub refurbishment!

Much like traditional spray refinishing it has a 24 hr cure time, but it is durable like a liner. This unique synthetic porcelain resin is poured over the tub surface which not only provides excellent adhesion for this permanent coating but is about five times thicker than traditional spray refinishing. Making this the most durable bathtub solution on the market, and it is backed with a 5 year warranty. Although proper care of the new surface can help it last over 25 years!

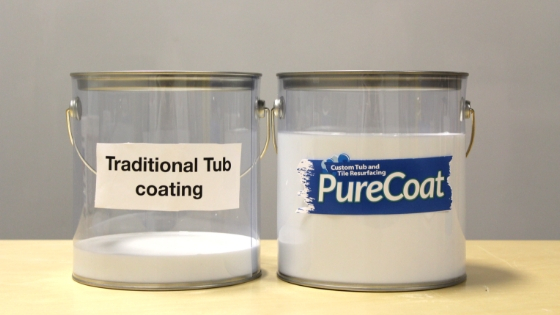

PureCoat is 5x thicker than traditionally sprayed on coatings! Sprayed on coatings, without fail, contain solvents which evaporate during the curing process in order to harden the coating. In fact, roughly 50% of the material that is sprayed onto a surface will evaporate during the curing period depending on the refinisher’s material ratios. But PureCoat is categorized as 100% solids and contains no solvents; meaning, what is applied to the tub stays on the tub. No more paying for coatings that disappear into thin air!

PureCoat is 5x thicker than traditionally sprayed on coatings! Sprayed on coatings, without fail, contain solvents which evaporate during the curing process in order to harden the coating. In fact, roughly 50% of the material that is sprayed onto a surface will evaporate during the curing period depending on the refinisher’s material ratios. But PureCoat is categorized as 100% solids and contains no solvents; meaning, what is applied to the tub stays on the tub. No more paying for coatings that disappear into thin air!