Why You Should Be Concerned For Your Health

The Dangers of Tub Resurfacing

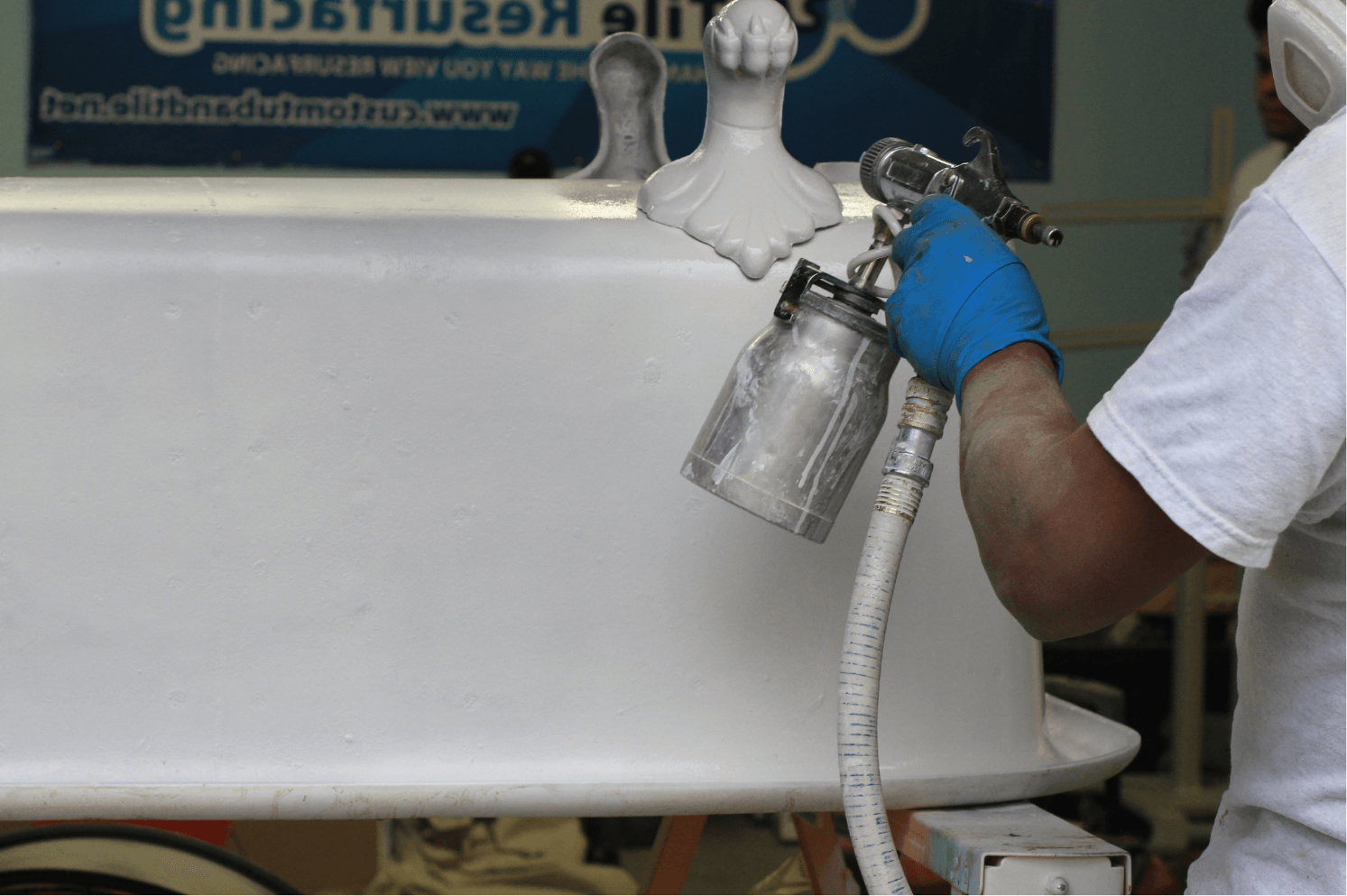

As homeowners we have all faced the dilemma of deciding between repairing something or replacing. What will help you get the biggest ROI if you are considering selling you home? In some cases, replacement could pay off in the long run, when it comes to things like appliances and fixtures. But what is often overlooked is the similar dilemma when it comes to bathtubs; refinish or replace? If you’ve done your research you know that chemical odor can be a cause for concern when it comes to refinishing, making replacement the more attractive option. That being said, it is important to know all of the risks and benefits of refinishing vs. replacement in order to make the most educated buying decision.

The Mess & The Money

Like all remodels, ripping out the existing bathtub to replace it with a new one is undeniably messy and loud. The process for replacement involves a large scope of skill-oriented work which is not necessarily DIY. First, the old plumbing will be disconnected to prep for the tub removal which can prove to be an arduous process if the plumbing is old. Then the tub is ripped out, and often broken into pieces, in order to fit through a doorway to be removed from the home. Oftentimes, the surrounding tile and sub flooring are damaged in the process. And the cost of a new tub varies depending on size and the material it is made out of as well as the amount of labor it takes to install it. Resurfacing the existing tub as an alternative to replacement can save you both time and money in your remodel. But it is important to note, that while resurfacing is cheaper than replacing the tub the unforeseen side-effects of the process could actually cost you more.

Methylene Chloride

It is not well known to the public the chemicals bathtub refinishers have been using day in and day out. But some of them have some pretty nasty side effects. One of those chemicals is called methylene chloride and it is found in some stripping agents, which help to remove the previous coating from the tub. Companies that use methylene chloride who are not properly equipped with a fresh-air respirator and a ventilation system run the risk of over-exposure for themselves and the people around them. This chemical causes so much concern that in 2013 the CDC stepped in because “14 workers since 2000 have died from exposure to methylene chloride.” That’s right, this methylene chloride runs the risk of killing those who use it. In high enough doses it affects cognitive brain function and can actually cause the user to stop breathing. Most people describe feeling of fatigue, dizziness, headaches, nausea, eye, nose, and throat irritation. And if that wasn’t bad enough, if it is left on the skin it can cause chemical burns and has even been linked to cancer.

It is important to note that there are stripping agents available that do not contain methylene chloride. And they are still effective at removing old coatings. Custom Tub & Tile does not use any resurfacing materials that contain methylene chloride. The safety and well-being of their resurfacing technicians and customers is of the utmost importance. Unfortunately, many resurfacing companies or individual refinishers know the risks associated with using methylene chloride but still choose to use it. It is important to ask your refinisher what products they are using in order to safeguard your family and yourself.

Isocyanates

Much like methylene chloride, isocyanates have some nasty side effects one must be aware of. Overexposure to isocyanates includes respiratory distress, such as asthma. Or hypersensitivity to pneumonia, cancer, lung disease, and respiratory irritation. Some other side effects include skin irritation, such as a rash or hives. But once the user has been overexposed to isocyanates they can never be around them again because of the intense breathing and skin issues they experience. Overexposure is caused by constant contact through the skin or lungs.

It is important to note that there are resurfacing coatings available that do not contain isocyanates. Custom Tub & Tile does not use any products that contain isocyanates. The safety and well-being of their resurfacing technicians and customers is of the utmost importance. Unfortunately, many resurfacing companies or individual refinishers know the risks associated with using isocyanates but still choose to use it. It is important to ask your refinisher what products they are using in order to safeguard your family and yourself.

Alternatives

There are valid alternatives to using products containing methylene chloride or isocyanates if one takes the time to look for them. The option that is completely devoid of chemicals is mechanical stripping of the old surface via sanding. It may take longer, be noisier, and require more elbow grease but in the end it can be just as effective if done properly. And there are also products for sale that do no contain life-threatening chemicals, which are the ones used by Custom Tub & Tile. But the best alternative would be to have a tub casting service performed on the tub. The coating is five times as thick as traditional spray refinishing, but without any odor. With its near zero VOC, tub casting is the greenest way to refinish your tub. It is the most expensive process, but can you really put a price tag in your health?