Tub Refinishing: A 1,500 Year Legacy

A 1,500 Year Legacy

Ever since the discovery of porcelain, there have been various methods of restoring and repairing surfaces; and these techniques are arguably as old as Chinese porcelain itself. The word porcelain is derived from the old Italian word porcellana, which was once a commonly used slang word for a cowrie shell; this was due to its resemblance to the shiny surface of a seashell. Roughly, about 1,200 – 2,000 years ago porcelain was evolved in China then slowly spread to other Asian countries and then finally Europe in the 1700s. Due to its more rigorous manufacturing process porcelain was typically regarded as the most prestigious type of pottery due to its delicacy, strength (compared to other earthenware), and its distinct white color.

Although it has proven it can withstand the test of time, that’s not to say that porcelain is impervious to daily wear and tear. The first documented porcelain item that has been repaired is several thousand years old. Artisans would make these delicate repairs using glue made from discarded animal parts and riveting, and these are widely regarded as some of the first rudimentary restoration techniques. Since the 600s to present day it remains true that repairs to porcelain surfaces require great mastery and experience, because it’s almost impossible to recreate the translucence of the fine white porcelain.

The Burgeoning Bathtub Industry

It wasn’t until the late 19th century that clawfoot tubs had reached the apex of its popularity in the western world; due largely in part to the popularity of increased attention to personal hygiene and the availability of indoor plumbing. Scottish inventor, David Buick, developed the process of bonding porcelain enamel to cast iron in the 1880s while working for a company in Detroit, Michigan. Kohler Company along with a few others helped streamline the production process and were able to market these porcelain-enameled cast-iron bathtubs to the public on a larger scale. Much like the auto industry, in 1929, the bathtub manufacturing industry evolved to offer their consumers a wider range of color options. Once bathrooms had reached their peak in terms of efficiency and sanitation, bathrooms then became viewed as a vehicle for design and household beauty. In other words, these trendy colors like avocado green and powder blue were considered a fashion statement for your home. Shortly after towards the end of the 20th century, the noble clawfoot tub was bypassed in popularity for the standard built-in tub with a small apron front. And later on, in the 1960s fiberglass bathtubs became more standard due to its lightweight frame and general inexpensive cost.

With Glaze Power Comes Glaze Responsibility

In the 1940’s America saw exponential growth in the use of porcelain coating appliances and with that undoubtedly came an increasing need for repairs. But the antiquated restoration techniques of using glue from repurposed animal parts and riveting has since evolved with the times. Refinishing is now widely accepted as the “new” way to update your porcelain enabled surfaces. “In the early 60’s porcelain refinishing companies like Ark®, PermaCeram®, Lik-Nu Porcelain®, and Electro-Glaze® entered into the bathtub refinishing business, becoming successful in their own right. These companies were purported as franchise and business opportunities, selling the rights to their name and the products that they would recommend to their refinishing dealers.” Currently, there are around 3,500 bathtub and tile resurfacing companies operating across North America.

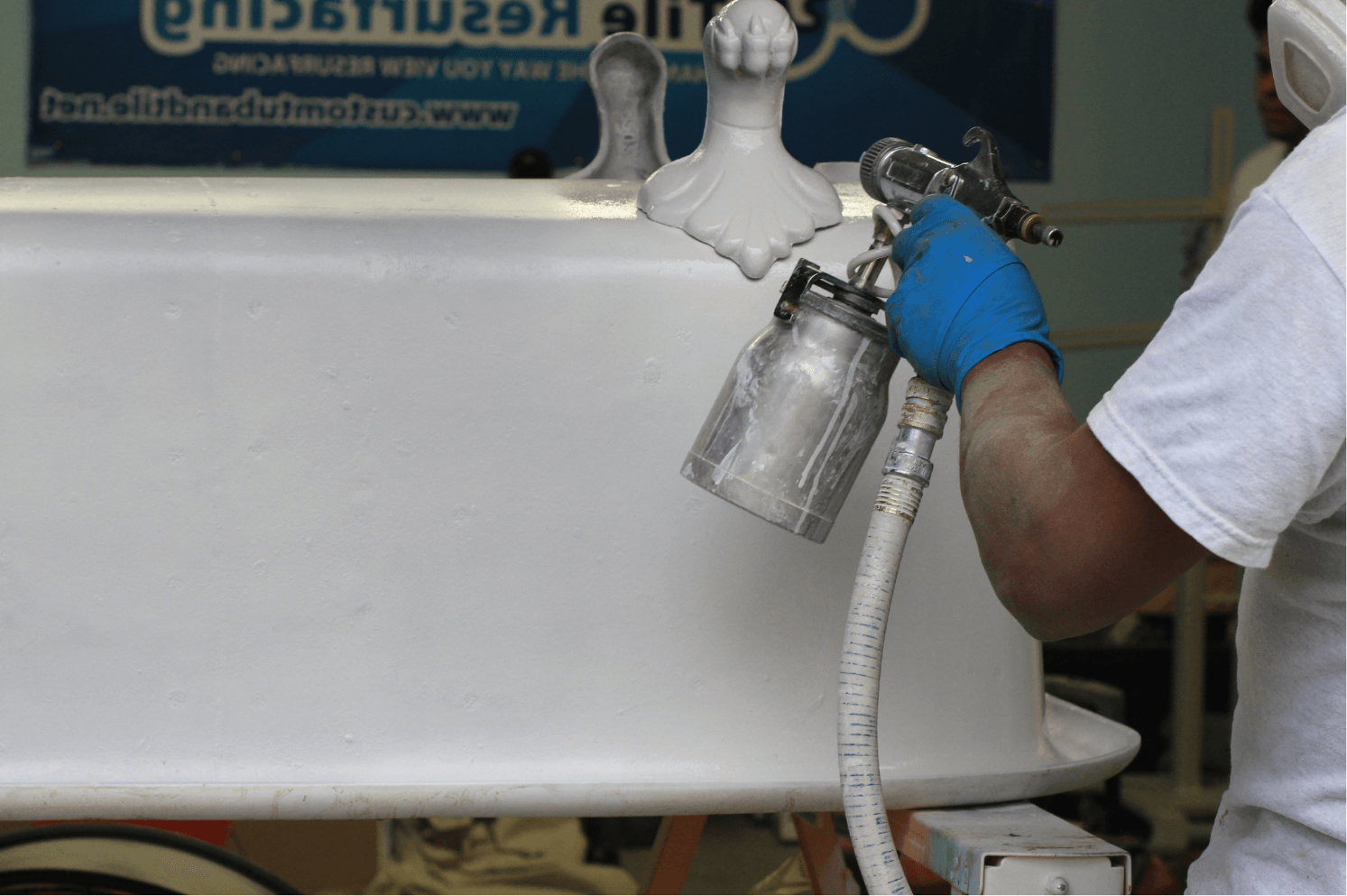

In modern times, bathtub refinishing can be described as the act of spraying a coating over your existing tub to make it look like new, repair minor damage, or to completely change the color. The goal of this cosmetic fix is to update your bathtub quickly, inexpensively, and without replacing a thing. It can be a stand-alone service or part of a larger remodel depending on the unique needs of the clients. And most tub resurfaces are completed in under 3 hours with a standard 24 hr dry time.

To learn more about repair techniques we use visit our blog, “3 Problems Resurfacing Can’t Fix”.

The Evolution Continues

The growing popularity of tub refinishing careers has lead to an ever-growing list of possible products to use, at varying price points. Unfortunately, some of these refinishing coatings (typically the more cost-friendly products) contain dangerous chemicals, like methylene chloride. Although the refinishing industry (and porcelain surface repairs in general) have come a long way, there are still improvements that can be made. As of November 22, 2019, the EPA has banned methylene chloride in paint strippers due to the health risks it poses, which is a good start. But you can rest assured that at Custom Tub & Tile we vow to never use products that contain isocyanates or methylene chloride because safety is our number one goal. Our tub casting system is not only environmentally friendly by contains no evaporating solvents giving it a near 0 VOC. The future is bright, thanks to innovative individuals, and we can’t wait to see how tub resurfacing, tub casting, and surface repair techniques will change over time.